ASME Section VIII Division 1 provides design, fabrication, inspection, and certification rules for pressure vessels operating over 15 psig, ensuring safety and compliance with industry standards․

Overview of the ASME Boiler and Pressure Vessel Code (BPVC)

The ASME Boiler and Pressure Vessel Code (BPVC) is a comprehensive standard for the design, construction, and certification of boilers and pressure vessels․ It ensures safety, reliability, and compliance with industry practices․ The BPVC is divided into multiple sections, with Section VIII specifically addressing pressure vessels․ Division 1 of Section VIII provides detailed rules for the construction of pressure vessels operating at pressures exceeding 15 psig․ It covers materials, welding, nondestructive examination, and certification requirements․ Regular updates and revisions ensure the code remains current with technological advancements and industry needs, making it a critical resource for engineers and manufacturers worldwide․

Scope and Exclusions of Section VIII Division 1

ASME Section VIII Division 1 governs the design, fabrication, and inspection of pressure vessels operating above 15 psig․ It applies to vessels such as boilers, tanks, and reactors but excludes piping, pipelines, and certain specialized equipment like aircraft and automotive vessels․ The scope also excludes vessels under direct jurisdiction of other codes or standards․ It specifies requirements for materials, welding, and testing but does not cover operation or maintenance․ This section ensures safety by providing clear guidelines for pressure vessel construction, balancing technical rigor with practical application across various industries․

Design Principles and Requirements

ASME Section VIII Division 1 establishes fundamental design principles and requirements for pressure vessels, ensuring safety through stress limits, material selection, and construction guidelines․

Design by Rules Methodology

The Design by Rules methodology in ASME Section VIII Division 1 provides a structured approach for designing pressure vessels, emphasizing adherence to predefined rules and standards․ This method relies on standardized formulas, charts, and material selection criteria to ensure compliance with safety and performance requirements․ It simplifies the design process by avoiding complex analyses, making it suitable for common vessel types․ The methodology includes guidelines for wall thickness calculations, stress limits, and fabrication techniques, ensuring consistency and reliability․ By following these rules, designers can efficiently produce vessels that meet code specifications and operate safely under specified conditions․

Allowable Stress Values and Material Selection

ASME Section VIII Division 1 provides detailed guidelines for determining allowable stress values, which are critical for ensuring the structural integrity of pressure vessels․ These values are derived from material properties, including tensile strength, yield strength, and creep resistance, and are adjusted for factors like temperature and design conditions․ Material selection is based on these stress values, ensuring compatibility with the intended application․ The code includes tables and charts that list maximum allowable stress values for various materials, enabling designers to make informed decisions while adhering to safety and performance standards․ This ensures vessels operate safely under specified conditions․

Design Formulas and Calculations

ASME Section VIII Division 1 provides essential design formulas and calculations to ensure pressure vessels are constructed safely and efficiently․ These formulas are used to determine shell thickness, head dimensions, and nozzle sizes based on operating conditions․ Key equations include those for hoop stress, axial stress, and radial stress, ensuring compliance with allowable limits․ Variables such as internal pressure, diameter, and material strength are factored into calculations․ Safety factors are incorporated to account for uncertainties, ensuring vessel integrity․ The section also includes charts and graphs to aid in determining design parameters for various vessel configurations and operating conditions, promoting accuracy and reliability․

Fabrication and Construction Guidelines

Fabrication guidelines ensure vessels are built to ASME standards, covering cutting, forming, fitting, and welding processes, with strict documentation for traceability and quality control․

Materials and Their Compliance Requirements

ASME Section VIII Division 1 specifies acceptable materials for pressure vessel construction, ensuring strength, durability, and safety under operational stress․ Materials must meet strict criteria, including chemical composition and mechanical properties․ Compliance requires suppliers to provide certified documentation, such as mill certificates, proving material traceability․ Permitted materials are listed in the code, with allowable stress values defined to prevent failure․ Traceability ensures every component can be verified for conformity․ This section also outlines testing requirements to validate material integrity, ensuring vessels are built to withstand design conditions safely and reliably․

Welding and Joining Techniques

ASME Section VIII Division 1 provides detailed guidelines for welding and joining techniques to ensure the structural integrity and safety of pressure vessels; Shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and gas tungsten arc welding (GTAW) are commonly specified methods․ The code outlines pre-qualification of welding procedures, welder certification, and inspection requirements․ Non-destructive testing (NDT) methods like radiography and ultrasonic testing are used to verify weld quality․ Proper documentation of welding processes is mandatory to comply with the code․ These standards ensure reliable and long-lasting joints, minimizing risks of failure under operational stresses․

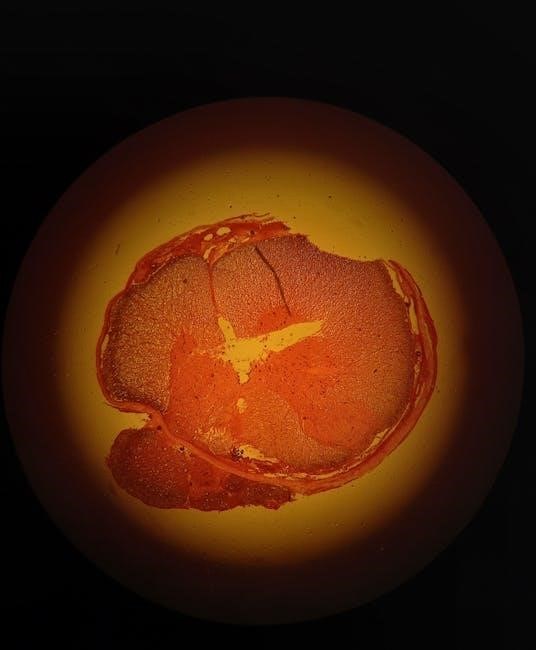

Nondestructive Examination (NDE) Methods

ASME Section VIII Division 1 mandates the use of Nondestructive Examination (NDE) methods to ensure the integrity of pressure vessel components․ Common techniques include radiography, ultrasonic testing, magnetic particle testing, and liquid penetrant testing․ These methods detect surface and internal defects without damaging the material․ The code specifies acceptance criteria, test frequencies, and qualification requirements for personnel․ Proper documentation of NDE results is essential for compliance․ These examinations are critical for verifying weld quality, material integrity, and overall vessel safety, ensuring adherence to the code’s stringent standards and minimizing the risk of operational failures․

Inspection, Testing, and Certification

Inspection, testing, and certification ensure pressure vessels meet ASME standards, involving visual checks, pressure tests, and documentation to verify compliance and operational safety․

Inspection Requirements and Procedures

Inspection requirements in ASME Section VIII Division 1 ensure pressure vessels are thoroughly examined for compliance․ Authorized Inspectors conduct visual and dimensional checks, verifying design and fabrication accuracy․ Nondestructive examination (NDE) methods, such as radiography or ultrasonic testing, are used to detect internal defects․ Procedures include documentation of all inspection activities, ensuring traceability and accountability․ Records must be maintained, detailing findings and any corrective actions․ Final approval is granted only after all inspections meet ASME standards, ensuring operational safety and reliability of the pressure vessel․ Compliance with these procedures is mandatory for certification and stamping․

Pressure Testing and Certification Processes

Pressure testing is a critical step to validate the structural integrity of pressure vessels under ASME Section VIII Division 1․ The code specifies two primary test methods: hydrostatic and pneumatic․ Hydrostatic testing is the most common, involving water pressurization to 1․5 times the design pressure․ Pneumatic testing uses air or gas at 1․2 times the design pressure․ Pre-test inspections ensure readiness, and post-test evaluations verify leak-tightness; Documentation includes records of pressure levels, duration, and temperature․ Successful testing leads to certification, with the vessel stamped by the inspecting authority․ Compliance ensures operational safety and adherence to ASME standards, validating the vessel for service․

Documentation and Compliance

Proper documentation ensures adherence to ASME Section VIII Division 1 requirements, including design calculations, material certificates, and test records, verifying compliance with safety standards and regulations․

Documentation Requirements for Compliance

ASME Section VIII Division 1 mandates detailed documentation to ensure compliance with design, fabrication, and testing standards․ This includes design calculations, material traceability records, welding procedure qualifications, and non-destructive testing results․ Documentation must also include certification marks, such as the ASME “U” stamp, verifying adherence to code requirements․ Proper record-keeping ensures traceability and accountability throughout the vessel’s lifecycle․ The ASME Section VIII Div 1 PDF provides specific guidelines for preparing and maintaining these documents, ensuring all aspects of the pressure vessel meet safety and regulatory standards․

Role of Certification Marks and Stamps

Certification marks and stamps play a critical role in verifying compliance with ASME Section VIII Division 1 standards․ The “U” stamp is a prominent certification mark, indicating that pressure vessels meet rigorous safety and design criteria․ Applied by Certified Individuals (CI), these stamps confirm adherence to code requirements․ They also facilitate traceability and accountability throughout the vessel’s lifecycle․ The ASME Section VIII Div 1 PDF outlines specific guidelines for stamp application, ensuring consistency and compliance․ These marks are essential for regulatory approval and operational safety, representing a vessel’s conformity to industry standards․

Appendices and References

ASME Section VIII Division 1 appendices provide supplementary information, while references guide users through related standards and essential publications for comprehensive code application․

Overview of Appendices in Section VIII Division 1

The appendices in ASME Section VIII Division 1 provide supplementary information to support the design, fabrication, and inspection processes․ They include guidelines for pressure vessel design, optional calculation methods, and material charts․ These appendices also cover nondestructive examination techniques and provide examples of design calculations․ While not mandatory, they offer valuable insights for engineers to ensure compliance with the code․ The appendices are regularly updated to reflect advancements in technology and industry practices, ensuring they remain relevant and useful for professionals working with pressure vessels․

Key References and Cross-References

The ASME Section VIII Division 1 PDF includes key references and cross-references to other sections of the Boiler and Pressure Vessel Code (BPVC)․ These references guide users to related standards, such as material specifications, welding standards, and nondestructive examination methods․ Cross-references help navigate interconnected topics, ensuring a comprehensive understanding of design, fabrication, and inspection requirements․ They also link to essential tables, charts, and appendices, avoiding duplication of information․ Regular updates ensure references align with current industry practices, providing engineers with accurate and relevant resources for compliance and best practices in pressure vessel construction․

Training and Professional Development

ASME Section VIII Division 1 PDF offers resources for professional growth, including training courses, workshops, and certifications․ These programs enhance expertise in pressure vessel design and compliance, ensuring proficiency in safety standards and code updates for engineers and fabricators․

Available Training Courses and Resources

ASME Section VIII Division 1 PDF provides access to comprehensive training courses and resources for professionals․ These include online courses, workshops, and seminars that cover design, fabrication, and inspection of pressure vessels․ Resources such as webinars, case studies, and interactive modules are designed to enhance understanding of code requirements․ Additionally, certification programs are available to ensure compliance with safety standards․ These tools are essential for engineers, fabricators, and inspectors to stay updated on code revisions and best practices, fostering continuous professional development and ensuring adherence to industry standards․

Building Professional Proficiency in ASME Section VIII Div 1

Building proficiency in ASME Section VIII Division 1 requires a combination of education, hands-on experience, and continuous learning․ Professionals should start by thoroughly understanding the code’s design principles, material requirements, and fabrication guidelines․ Practical application through simulations and real-world projects enhances problem-solving skills․ Mentorship from experienced engineers and participation in industry forums can provide valuable insights․ Staying updated with the latest revisions and attending specialized training programs ensures compliance with current standards․ Leveraging the ASME Section VIII Div 1 PDF as a reference tool is essential for quick access to detailed information and best practices․

Historical Perspective and Revisions

ASME Section VIII Division 1 originated in 1915, with revisions reflecting industry advancements and safety standards․ Updates ensure compliance with modern engineering practices and materials․

Evolution of ASME Section VIII Division 1

ASME Section VIII Division 1 has evolved significantly since its first publication in 1915․ Initially developed to address the growing demand for standardized pressure vessel design, it has undergone numerous revisions to incorporate advances in materials, design methodologies, and safety requirements․ Key updates include the introduction of stress analysis in the 1930s, the addition of Division 2 in the 1960s for alternative design approaches, and the integration of finite element analysis in the 2006 edition․ These changes reflect the industry’s commitment to improving safety, efficiency, and compliance with global engineering standards․

Recent Revisions and Code Cases

ASME Section VIII Division 1 has seen significant updates in recent years, with the 2021 and 2023 editions introducing key revisions․ These include enhanced guidelines for additive manufacturing, updated material allowable stress values, and improved welding and nondestructive examination (NDE) standards․ Code Cases now provide interim interpretations and approvals for emerging technologies, such as the use of advanced materials and digital manufacturing techniques․ These revisions aim to address modern engineering challenges while maintaining safety and compliance standards․ They reflect the continuous evolution of pressure vessel design and fabrication practices, ensuring alignment with global industrial advancements and regulatory expectations․

ASME Section VIII Division 1 PDF Document

The ASME Section VIII Division 1 PDF provides detailed technical requirements for pressure vessel design, materials, fabrication, and testing․ It includes key sections, appendices, and updates․

Structure and Content of the PDF

The ASME Section VIII Division 1 PDF is organized into multiple chapters and appendices, covering design, materials, fabrication, and testing․ It includes tables, charts, and equations for pressure vessel design, along with detailed requirements for allowable stress values, weld joint efficiencies, and nondestructive examination methods․ Key sections address design by rules, pressure relief, and certification processes․ Appendices provide supplementary information, such as design formulas, material properties, and guidance for special cases․ The document also includes cross-references to other ASME standards and guidelines for compliance with international codes and standards․

Key Sections and Chapters in the PDF

The ASME Section VIII Division 1 PDF includes key sections such as Chapter 1 (General Requirements), Chapter 2 (Design Requirements), and Chapter 3 (Materials)․ Chapter 4 focuses on pressure relief devices, while Chapter 5 covers nondestructive examination methods․ Chapter 6 addresses fabrication requirements, and Chapter 7 details testing procedures․ Chapter 8 provides certification guidelines, and Chapter 9 covers high-pressure vessels․ These chapters ensure comprehensive coverage of design, safety, and compliance, offering detailed guidance for engineers and fabricators to meet industry standards and regulatory requirements effectively․